APPLICATION

- Home

- application

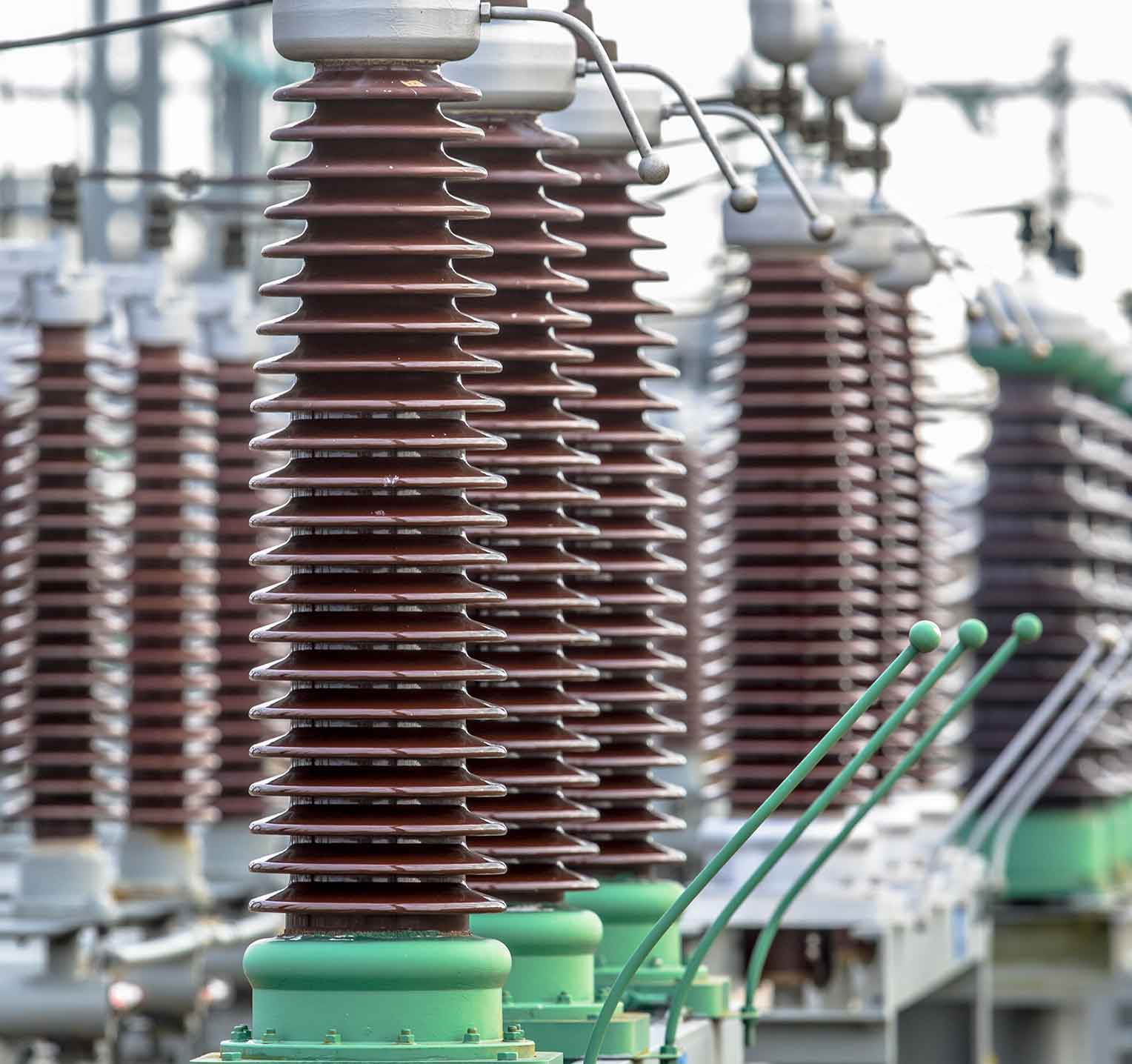

Power Industry

Transformer Oil &

Lubrication Systems

In power systems, the cleanliness of transformer oil and lubrication oil directly affects insulation performance and operational safety. Fine particles and moisture generated during long-term operation can accelerate equipment aging and increase failure risks if not effectively removed. Reliable and stable filtration materials are essential to ensuring safe and continuous operation of power equipment.

Fine particles and moisture reduce insulation performance

Long-term operation requires highly stable filter materials

Neutral pH industrial filter paper with high moisture absorption

Stable filtration suitable for continuous operation

Petrochemical Industry

Oil & Chemical Liquid Filtration

In petroleum and petrochemical processes, oils and chemical liquids often contain complex components and high levels of impurities. Filtration systems must operate reliably under high-temperature and high-pressure conditions, placing higher demands on the strength, oil resistance, and consistency of filter paper.

Complex liquids with high impurity levels

Filter materials degrade under high temperature and pressure

High-strength, oil-resistant industrial filter paper

Customizable specifications to match equipment

Contact us to learn more about industry application scenarios

Providing stable and dependable filtration solutions across multiple industries

Matching filtration materials to diverse operating conditions

Machinery & Metal Processing

Cutting Fluid &

Emulsion Filtration

In machinery manufacturing and metal processing, cutting fluids and emulsions are used for cooling, lubrication, and cleaning. If metal chips and contaminants are not effectively filtered, machining accuracy may be reduced and the service life of equipment and tools may be shortened.

Metal chips and impurities accelerate equipment wear

Poor filtration reduces machining accuracy

Uniform-structure filter paper with stable efficiency

Extended service life of cutting fluids

Research Institutions

Analytical Filtration

Laboratories and research institutions require extremely high accuracy and repeatability in filtration processes. The purity, ash content, and structural uniformity of filter paper directly affect the accuracy and reliability of analytical results.

High requirements for purity and consistency

Ash residue may affect analytical accuracy

High-purity cotton fiber analytical filter paper

Clear differentiation between qualitative and quantitative grades

Common Questions

Most Popular Questions

We manufacture industrial filter paper, qualitative filter paper, quantitative filter paper, and selected specialty paper products, widely used in power, petroleum, chemical, machining, laboratory, and environmental applications.

Our industrial filter paper is widely used in power generation, petroleum refining, chemical processing, machinery manufacturing, metallurgy, pharmaceutical, food, and environmental industries, particularly for oil and industrial liquid filtration.

Yes. We offer customized solutions in basis weight, size, filtration speed, and performance parameters to match specific equipment and operating conditions.

Selection depends on the filtered medium, particle size, and required filtration precision. Our technical team can assist in selecting the appropriate grade.

Yes. We are ISO9001 certified and operate a comprehensive quality control and inspection system to ensure consistent and reliable product performance.

Under normal operating conditions, our industrial filter paper typically offers more than twice the service life of ordinary filter oil paper, depending on the application environment.

MOQ varies depending on product type and specifications. Standard products follow regular MOQ, while customized items can be discussed.

Samples can be provided upon request, subject to availability, to help customers evaluate suitability for their applications.

You can contact us via the website inquiry form, phone, or email. Our sales and technical teams will respond promptly.

Standard products have stable lead times, while customized products depend on specifications and order volume.